In February 2022, we entered the Lunar Year of the Tiger. Fittingly, semiconductor demand is as ferocious as the tiger and shows no signs of easing up soon. To meet this demand, the industry must be as efficient as possible.

In this regard, the tiger is not the best role model. Even though the tiger is the king of beasts according to Chinese tradition and deserves respect, it is a very inefficient hunter. The tiger’s catch-to-chase efficiency is 5%. A yield that low would put any fab out of business in a hurry. We must be far more efficient than the tiger. Even the cheetah’s efficiency rating of 58% would not be an acceptable yield.

The tiger needs only to catch enough prey to sustain itself. When species populations are in balance, a result of 5% will meet its needs. But if the supply of game drops, the tiger must improve its efficiency through better hunting tactics, or it will starve. This lesson is relevant to the semiconductor industry.

Semiconductor manufacturing must far outpace the tiger and cheetah (i.e., yield above 95%) to keep pace with demand. That is true regardless of where we are in the cyclical market. With today’s supply chain pressures, the situation is more challenging. When the supply chain is out of balance and demand for chips greatly outpaces supply, it becomes harder to deliver the quantities your customers need.

Each new fab greatly expands capacity, but building one costs years and millions or billions of dollars. When you run the numbers, you might find that investments in additional facilities or equipment are a beneficial long-term solution. But that will not help much if you need to bump up productivity immediately.

How can you achieve more from your existing equipment? Increasing yield above your typical performance is the fastest way to improve your chances in the marketplace. When you audit your processes to discover where the yield losses are occurring, you can take steps to close the gaps.

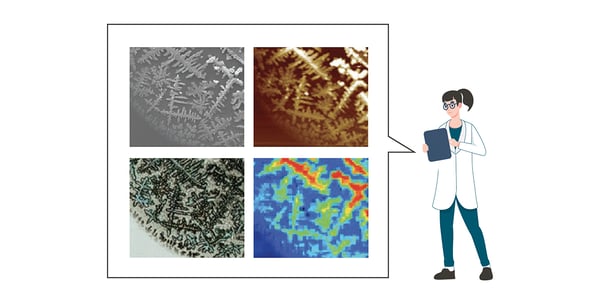

Figure 1. Examining sources of process variability.

Figure 1. Examining sources of process variability.

You may benefit from a “tiger team,” a cross-functional team that works together to solve a specific, urgent problem quickly. Collaboration has always been essential, and now it is even more so. One improvement is not likely to produce even a 1% yield gain. By combining several approaches, you multiply your success. Like the tiger faced with declining numbers of prey, you must look harder and perhaps beyond your usual strategies to get the desired results.

Each process step in logic, 3D NAND, and DRAM memory manufacturing is interdependent. The more advanced the process node, the greater the sensitivity to even the smallest defect. The greater the number of layers, the more defects compound to reduce yield.

Every step of the manufacturing process represents an opportunity to minimize yield loss. Contamination control is a critical strategy that applies to deposition, photolithography, wet etch, and clean steps—the purer the incoming materials and the cleaner the equipment, the lower the risk of defects. Entegris offers multiple products designed to reduce contamination and improve purity, increasing yield.

Before racing off like a young tiger chasing anything that moves, it is wise to scan your surroundings carefully. Mature tigers leverage their instinct and experience to go after the weakest prey. Similarly, fabs will benefit from a holistic audit of your entire process to determine which sources of yield loss are the greatest and which are easiest to stem. Your tiger team can carry out the audit. Results may vary by product line, so it is essential to involve personnel with varied experience for optimum collaboration. The process will work best when you include suppliers in the discussion.

With the knowledge gained from your yield audit, you can create a targeted, efficient plan. Perhaps improving CMP yield or reducing chamber contamination is the best first step. It might be better to start by increasing chemical or gas purity throughout your supply chain. You will likely want to implement several of these or other tactics and track results to determine how well your changes are working and whether more yield improvements are possible.

Figure 2. Collaboration across the supply chain.

Figure 2. Collaboration across the supply chain.

Instincts or guesswork will not get you very far toward the yield improvements you need to compete in today’s high-stakes market. A carefully designed, multi-pronged approach will be much more successful. We will help you identify sources of variability and connect you with the right solutions to improve yield across your operation.