Understanding potential sources of contamination and developing targeted filtration solutions in 30% H2O2

Demand for ultra-pure chemicals—especially hydrogen peroxide (H₂O₂)—has never been higher as defect tolerances tighten with more complex IC designs. H₂O₂ is critical in wet etch, clean, and chemical mechanical polishing (CMP) processes, but its strong oxidizing nature and diverse contamination profile make effective filtration both essential and challenging. Hydrogen peroxide used in semiconductor manufacturing contains a complex mixture of contaminants which can originate from raw materials, production processes, or even packaging/handling materials, and these contaminants can be in dissolved or solid/semi-solid forms in a variety of forms/sizes:

- Hard particles (inorganic, organic)

- Soft particles (gels and polymers)

- Dissolved ions (cations and anions)

- Organics (residues, volatiles and semi-volatiles)

Objectives of the study

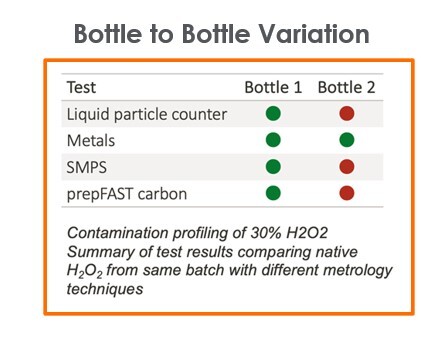

- Utilizing a hybrid metrology approach to understand the variability within the same batch of electronic grade H2O2 due to its packaging containers.

- Leveraging the hybrid metrology approach to evaluate the effectiveness of standard nanoparticle retention tests in predicting performance of two PTFE membranes in filtering contaminants natively present in 30% H2O2.

Findings

Packaging containers have a significant impact on final chemical quality – the testing highlighted that despite being sourced from the same manufacturing batch, there were significant differences in the final material when analyzed by a suite advanced metrology tool, each screening for different type of contaminant of concern for semiconductor manufacturing process. The variability in the final material is most likely due to leaching from the packing container (HDPE) over the duration of storage and transport.

For the study on filtration, it was observed that depending on the standard particle used, there can be some guidance discerned on filtration efficiency of membranes. But these standard particles are not representative of the contamination natively present in these semi-grade chemicals. With the analysis of the chemicals using a combination of advanced analytical techniques, pre and post filtration - A more complete picture can be developed of what each filter is really removing.

By gathering and reviewing this type of data early in the filter selection process – Entegris can help provide optimized filter recommendations that target the true contaminants of concern at various points of filtration.

Watch Lead Author, Kusum Maharjan describes the study.

To read the full study, download the Tech Note summary or contact us to learn more with the Entegris experts.