Shrinking feature size, advances in interconnect metals, and the need for ever tighter defectivity control all point to the growing importance of chemical mechanical planarization (CMP) to optimize fab yields. More layers of each chip require CMP to achieve planarity specifications, and contamination must be kept to a minimum.

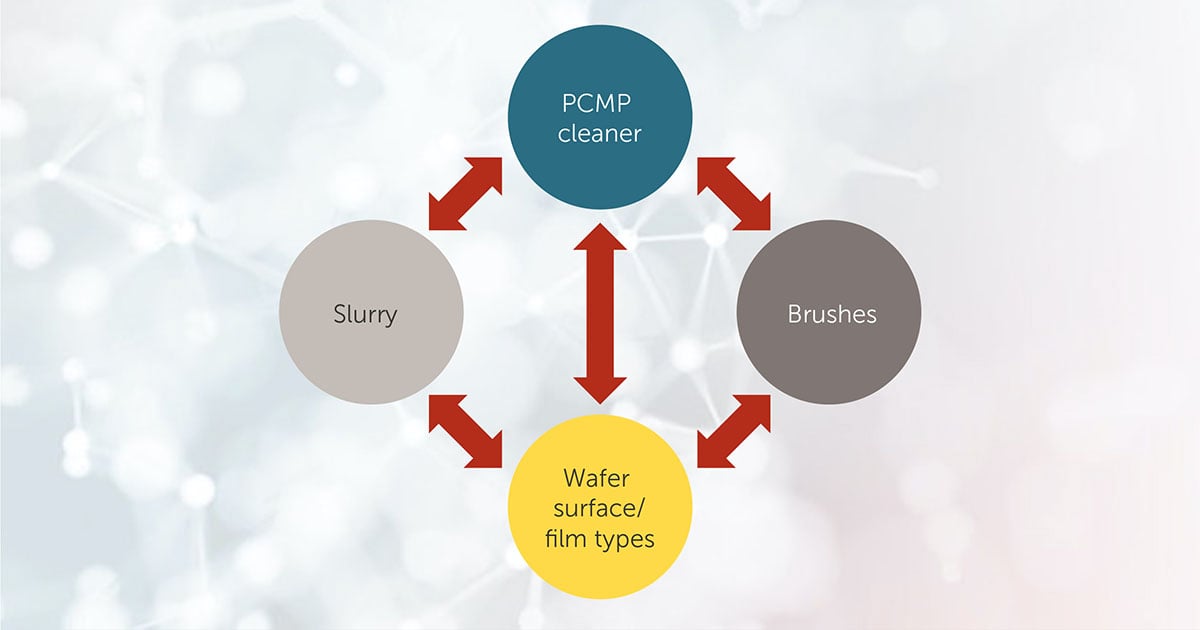

It is critical that all chemicals and consumables related to the CMP process are compatible with one another. This synergistic approach to CMP must encompass all the materials, components, and equipment that are related to the process. The list includes, but is not limited to, the following:

- Slurry abrasives

- Slurry additives

- Storage containers

- Fluid handling components

- Clean formulations

- Brushes

- Filters

- Process monitors

Synergies between various aspects of the CMP process and post-CMP clean

The Slurry

The slurry is the most important part of the CMP process. It serves a simple purpose—removing a thin layer of metal or oxide using a combination of abrasive particles and chemical additives. Slurries are becoming more complex because of the need to polish various metals. Formulations designed for copper will not achieve the same results on molybdenum, tungsten, cobalt, or ruthenium.

The mix of additives such as oxidizing chemicals, corrosion inhibitors, stabilizers, surfactants must be optimized to control the metal removal rate and ensure consistent results for the specific application. The concentration of hydrogen peroxide (H2O2), which oxidizes the metal, degrades over time, so slurry storage is another important consideration.

Contamination must be minimized throughout slurry blending, storage, transport, and handling. As the slurry passes through tubing, valves, and other components of the fluid handling system, it can pick up contaminants. Components made from inert, corrosion-resistant fluoropolymer materials are ideal because they will not shed particles that degrade the slurry.

The abrasive particles in the slurry tend to agglomerate, clumping together to form large particles that cause micro-scratches on the wafer. The larger the scratches and the finer the features on the wafer, the greater the likelihood of killer defects. System designs that minimize dead space where particles can settle reduce the incidence of agglomeration.

Cleaning and Filtration

Materials and chemicals for post-CMP cleaning must be compatible with the CMP slurry and avoid introducing additional sources of contamination. Surface and galvanic corrosion from the clean is one issue, and reactions between additives in the slurry and those in the clean can create organic residues.

The brushes used in post-CMP cleaning should be designed to achieve uniform fluid distribution on the brush surface. Brush materials with a high zeta potential allow the brush surface to repel slurry particles that might otherwise adhere to the brush surface and scratch the wafer.

Regardless of the materials in the system, filtration is critical. Filters should be installed at multiple locations so that they can capture contaminants and agglomerated slurry abrasives before they reach the wafer.

Filtration to remove large particles—those around twice the nominal particle diameter or larger—has long been commonplace in CMP systems. Next-generation filters will be able to remove particles at both ends of the size distribution simultaneously. Extremely small particles, which can introduce underlayer defects, are absorbed onto the filter surface.

Process Monitoring

It is important to monitor the CMP process to determine when to swap out filters to maximize filter lifetime without sacrificing yield. Waiting until yield decreases to replace filters is an expensive, inefficient approach.

Monitors not only inform filter replacement but also serve as an in-process check on slurry composition, particle agglomeration, and fluid handing system performance. Analytical instruments integrated into the CMP process flow can automatically titrate samples, while lower cost tools that measure the index of refraction can be installed at every polishing station offer a process check. Flow rate meters ensure proper blending ratios during slurry mixing and monitor fluid flow rate throughout the system.

When the entire system works in sync, contamination decreases and fabs are best able to achieve their yield goals for the CMP process. The more stringent the performance requirements, the more important it is for all aspects of the CMP system to support the slurry. Sourcing the slurry, filters, components, and monitoring tools from a single supplier makes it much easier to streamline the process, decrease cost of ownership, and ensure high yield.

For more details, see the Entegris white paper, “Particles, Processes, and Planning: Synergies to Improve CMP Yield.”