Inconsistent results and deviation are major issues in cell therapy manufacturing, primarily resulting from historically manual methods, scarcity of proprietary tools, and lack of operator training. With this difficult process also comes another hurdle–time. Providing a safe vein-to-vein transmission is critical when a patient is waiting (in many cases) for lifesaving therapy. How can we bridge the gap between speed, quality, safety, and consistency?

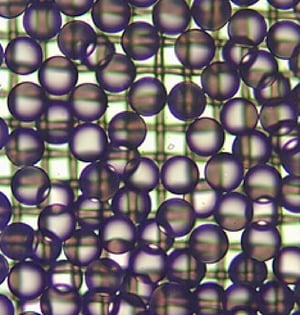

Magnetic beads have been the benchmark for cell and gene therapy (CGT), and the FDA holds strict requirements for their removal in CGT processing. Current methods require expensive, complex equipment, costly infrastructure, and highly skilled personnel. Despite specialized training, a single individual still needs to operate the process impeccably each time and avoid risking contamination.

Through the Magnetic Bead Removal Using Microcarrier and Cell Separation Study, Entegris’ microcarrier and cell separation system was incorporated into an optimized bioreactor subculturing process to maximize viable cell recovery and obtain a high split ratio between bioreactors during scale-up. At the end of each bioreactor run, a small volume of culture was taken as a representative sample of the entire culture. This sample was processed using the conventional tube method and the yield obtained was considered 100% cell recovery.

Through the Magnetic Bead Removal Using Microcarrier and Cell Separation Study, Entegris’ microcarrier and cell separation system was incorporated into an optimized bioreactor subculturing process to maximize viable cell recovery and obtain a high split ratio between bioreactors during scale-up. At the end of each bioreactor run, a small volume of culture was taken as a representative sample of the entire culture. This sample was processed using the conventional tube method and the yield obtained was considered 100% cell recovery.

With customized chamber and mesh sizes (10 - 200 µm), the microcarrier and cell separation system can be used for a wide array of applications such as retaining aggregate cells or microcarrier beads, cell washing, and harvest, all while achieving the same or better performance as alternative separation methods.

Our closed microcarrier and cell separation system provides scalability, compatibility with a wide array of microcarriers, and can reduce deviations . Entegris is the only manufacturer of small bags specifically built for cells. By partnering with us, you’ll be able to increase yield, reduce deviations, and avoid the risk of residual beads in your final product.

To learn more read our application note.