As a world-class supplier of advanced materials and process solutions for the semiconductor space, we understand the complexity and challenges of quality by design with respect to bulk drug cold chain manufacturing. Costly failures can be devastating and, in many cases, can be avoided by partnering with the correct single-use solutions provider to help optimize critical processes. When looking for solutions to protect your therapeutics during bulk drug cold chain, keep the following in mind:

Protection

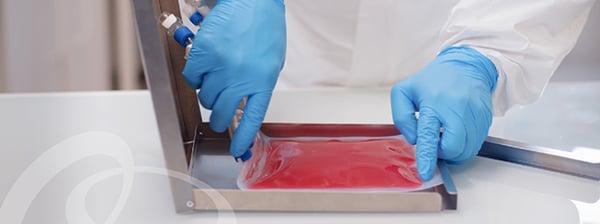

Is your current single-use solution performing up to regulatory standards? Safeguard your high value therapeutics from reactive, absorptive, additive single-use solutions that can compromise drug effectiveness by choosing a robust, inert material that can handle temperatures of -196°C (-320°F) while maintaining its physical properties. The right material will protect the integrity, efficacy, and purity of your product, which in many cases can be as important as the product itself.

Secondary Containment

Secondary Containment

Can your secondary containment withstand transport and storage challenges? Optimizing for controlled freeze/thaw and transport can help you get the most out of your process, saving time, money, and resources. Shells offering low storage density, freezer compatibility, intra-facility transfer, and frozen distribution enable maximum protection. These containment shells can be customized per application, offering high-quality throughput in an economical package. From lower cost intermediaries to high end therapeutics, Entegris shells offer maximum protection throughout the cold chain process.

Technology

Proper design and process capabilities are vital requirements when developing solutions to protect high value product, which ultimately creates opportunities to develop solutions in the protection of high value therapeutics. With the single-use market for bioprocess at $8B and growing, there is a tremendous need to move from traditional stainless steel to single-use technologies. We are a trusted partner that provides robust and reliable single-use solutions for bulk drug freeze, thaw, and transport. This is evident in the launch of our Life Sciences Technology Center. The Technology Center is open to partners looking to create high purity, robust solutions designed specifically for their process. Designed around our primary consumable, Aramus™ single-use bag assemblies, we combine world-class hardware with a complete plate freezing solution delivering quality by design systems.

By partnering with Entegris, you will reap the benefits of our expertise in cold-chain process and operations, bespoke solutions tailored to your process, and a working partnership with a well-resourced freeze/thaw ecosystem center. We back this with our robust global supply chain, operational excellence, and technology investments.

By partnering with Entegris, you will reap the benefits of our expertise in cold-chain process and operations, bespoke solutions tailored to your process, and a working partnership with a well-resourced freeze/thaw ecosystem center. We back this with our robust global supply chain, operational excellence, and technology investments.