Last year, Semiconductor Digest assembled six panelists from the world's leading semiconductor and automotive manufacturers and suppliers - including Volkswagen, Texas Instruments, Robert Bosch, Hyperion, and KLA, and Entegris - and asked them about the state of automotive electronics. They discussed issues such as the shift to automotive quad computing, the emphasis on infotainment, and the rise of alternative vehicle technologies such as electrification and self-driving.

This year, we invited many of those same panelists together and asked them what’s changed. A year may seem like a short time, but it’s a long time in the world of technology. In 12 months, chipmakers and automakers have discovered new production strategies, changed their quality and reliability standards, and altered their partnerships. Has it been for the better?

The broad consensus is that one year has made a tremendous difference. Panelists agreed that as the technology powering cars has changed, there’s also been a sea change in terms of policy and customer preference. This has led to greater investment in automotive electronics by both established manufacturers and suppliers as well as newcomers to the marketplace.

Figure 1. 2023 Panelists

A Shift from Autonomy to Vehicle Electrification

On the technology side, in-car electronics have crystalized around enabling electric vehicles. Entegris’ VP of Market Strategy, Wenge Yang, noted that back in 2022, the industry prioritized self-driving over electrification. This has since changed, with most automakers understanding that they need to tackle electrification first. That’s because many of the technologies required for full autonomy still remain in their infancy. While the industry waits for those technologies to come online, electrification is viewed as the more urgent priority.

In addition, some policy outcomes – such as passage of the landmark Inflation Reduction Act – have led to broader consumer adoption. Electric vehicles now represent 5% of the total vehicle market in the U.S., which is potentially a tipping point for much wider acceptance There’s a clear incentive for automakers to pursue electrification above all else.

The shift to electrification has led to some technological challenges. Silicon carbide is preferred for power electronics in electric vehicles, but it lacks some of the inherent reliability of pure silicon. Even traditional manufacturers are deploying chips down to the 3-4 nm range. This deployment brings reliability challenges of its own.

Meanwhile, automotive quality standards aren’t budging. Automakers typically require a zero-fail lifespan of 15 years for automotive components. To meet quality standards, chipmakers must collaborate with automakers across the supply chain.

Chipmakers are Specializing in Automotive Semiconductors

Many semiconductor manufacturers are beginning to realize that automotive quality standards preclude off-the-shelf chip designs. Instead, chipmakers are beginning to cater specifically to automakers and OEMs with specialized fabs containing unique tools and testing fleets.

While established semiconductor manufacturers may have been working on automotive chips for decades, newcomers have worked on totally different mission profiles in the past. As a result, they may be struggling to reach automotive quality targets. This has sparked some discussion around standardization. On the one hand, some level of standardization is required to develop robust technology. On the other hand, if newer chipmakers are struggling to meet existing quality standards, new standards may impose an additional barrier to entry.

What is the Best Way for Chipmakers and Automakers to Work Together?

Even if standardization remains contentious, there are other ways for chipmakers and automakers to collaborate. Part of this means closing the communication gap. At Texas Instruments, key stakeholders have realized that automakers are still learning how reliability is built into their systems with greater semiconductor quality standards. By having an open channel for communication, the company has been able to reduce cycle time for future engagements with their automotive partners.

Having open communication channels does more than just ensure product quality. It can ensure supply chain quality as well. Because vehicles can use so many integrated circuits – up to 3,000 in some cases – minor disruptions can have a large impact on auto production. When chipmakers and automakers have open lines of communication, they can have honest discussions about change management. This means faster recovery and a remedy for the vehicle production slowdowns we’ve seen over the past few years.

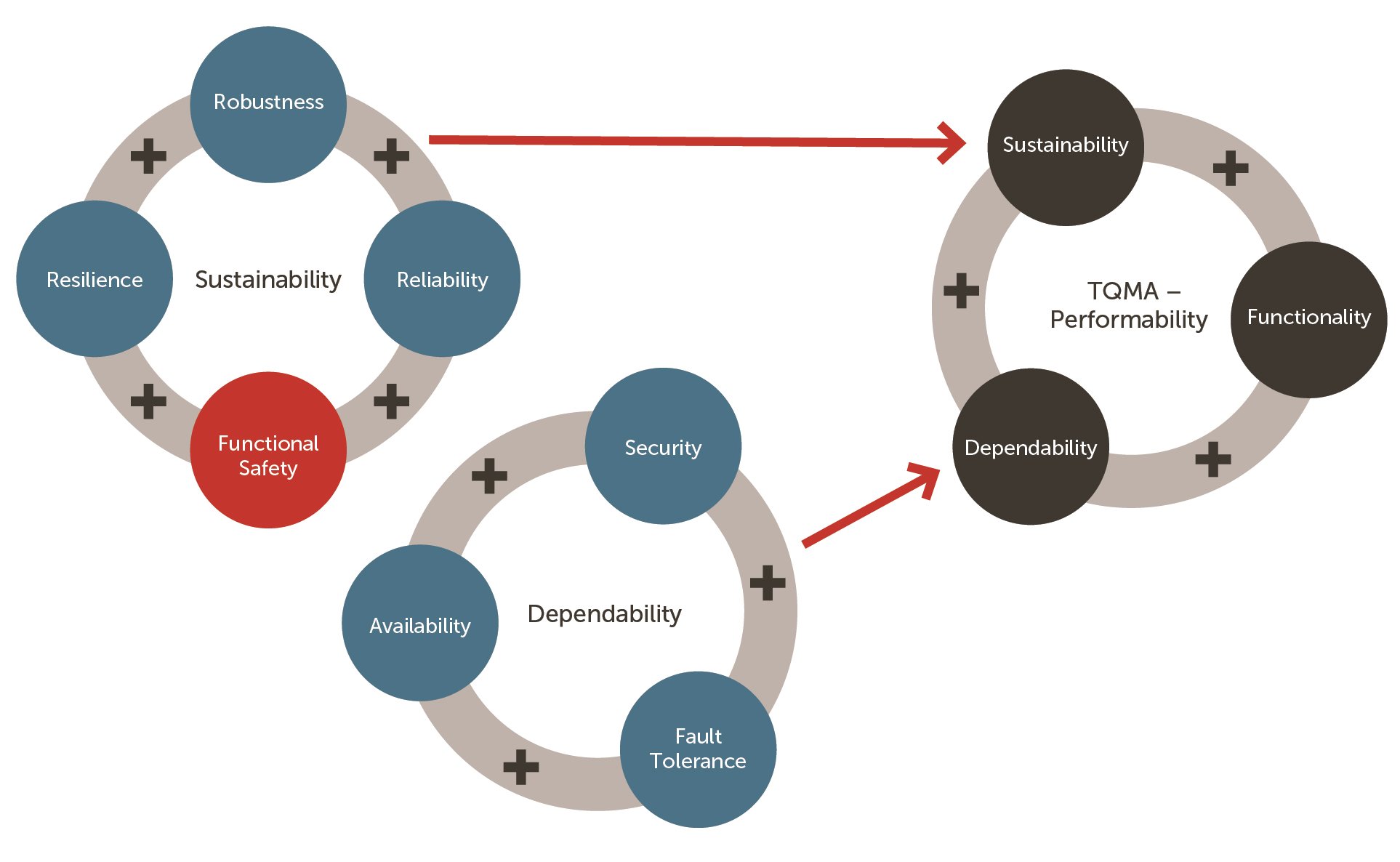

Figure 2. Total quality management

Lastly, when top-performing chipmakers demonstrate success by collaborating with automakers, the entire industry follows suit. Semiconductor manufacturers are realizing that their most reliable competitors in the automotive market are collaborating with automakers directly. They’ll then try to model that same performance. When this reliability is the result of collaboration, increased collaboration efforts will naturally occur.

Where Do We Go From Here?

In just 12 months, automakers and semiconductor manufacturers have formed revolutionary partnerships. Instead of reacting to supply chain issues or pursuing technologies of the future, they’re collaborating proactively on very real and near-term challenges. Despite obstacles such as disagreements on standardization, open lines of communication have allowed these partnerships to flourish.

Figure 3. New Collaborative Approach

This collaboration has borne positive results throughout the supply chain by bridging the knowledge gap required to design and build better chips for the industry. Such partnerships may be transforming the way that automakers think about their product. Instead of selling cars, automakers are selling “mobility as a service,” a connected vehicle that provides information both to passengers and smart cities to generate more pleasant driving experiences. In the very short term, we may see that the most powerful computer that most consumers own is the one in their car.

For more information on automotive reliability in the semiconductor industry, watch the on-demand webinar today and visit our New Collaborative Approach page.