Lithographer’s face the challenge to translate designs into reproducible patterns that meet their yield, parametric performance, and reliability goals. Success or failure relies heavily on the controls in place that limit process variation. Recognizing and addressing all the sources of lithography pattern variations can preoccupy lithographers.

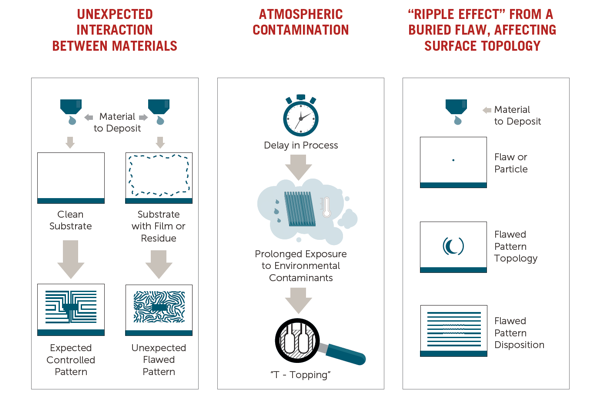

Hence the question, where can pattern flaws originate?

Click the image to see this process in motion

You’re not alone in mitigating these challenges. Collaboration between fabs, equipment makers, materials suppliers, and designers can lead to a more holistic approach to finding the root cause.

Join the conversation at www.entegris.com/pattern to identify the sources of your pattern integrity challenges.