Exploring the Superiority of Silicon Carbide in Optical Components

Silicon carbide (SiC) is a leading material for high-performance optical components, offering numerous advantages over traditional materials such as glass and metal. Its exceptional specific stiffness, high thermal conductivity, and outstanding dimensional stability position SiC as a superior choice compared to beryllium and low-expansion glass ceramics.

Historically, the high costs associated with the preliminary shaping and final finishing of SiC have hindered its widespread adoption in optical systems. The material is both hard and strong, requiring precision machining with expensive diamond tooling on high-quality, rigid machine tools. However, advances in manufacturing techniques, such as near-net-shape slip casting, have demonstrated success in reducing costs despite necessitating significant diamond grinding.

Building on this success, Entegris offers an entirely new way of creating SiC. Using our chemical vapor conversion process, we can create net- or near net-shaped SiC components in complex forms while spending much less time on fabrication.

Innovative Fabrication Process

Entegris’ innovative chemical vapor conversion process begins with machining the component from a specialized type of graphite. This graphite can be rapidly and efficiently machined using conventional multi-axis CNC machines, allowing for complex designs and lightweight structures. Once the desired shape is achieved, the graphite is fully converted into SiC, resulting in minimal and predictable dimensional changes.

After conversion to SiC, the optical surface is coated with very fine grain SiC using chemical vapor deposition, which is easily polished to extreme smoothness. This fabrication process not only streamlines production but also enhances the performance of the final optical components.

In this video, learn how Entegris harnesses chemical vapor conversion to rapidly create space optics components from silicon carbide.

The Benefits of Silicon Carbide

SiC stands out as an optimal material for mirror optics due to its remarkable combination of thermal and mechanical properties. It exhibits excellent long-term dimensional stability even under extreme environmental conditions such as significant temperature and humidity fluctuations and exposure to corrosive substances.

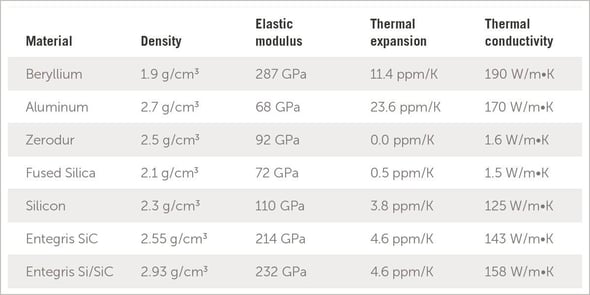

With a specific stiffness comparable to beryllium, SiC's density is slightly higher than aluminum, but its elastic modulus surpasses that of beryllium, depending on how it is processed. Unlike many ceramics that typically have low thermal conductivity, SiC excels with thermal conductivity that rivals some metals. This unique combination of high thermal conductivity and low thermal expansion makes SiC ideal for optics and mechanical structures that require resistance to thermal distortion.

Property Comparison Between Entegris SUPERSiC® Silicon Carbide Materials and Other Materials Currently Being Used in the Manufacturing of Mirrors

Thermal Stability and Performance

Silicon carbide’s low thermal expansion ensures that mirrors and precision structures experience minimal movement when subjected to sudden or uneven temperature changes, such as those encountered in space-borne telescopes. The high thermal conductivity allows for rapid dissipation of temperature differentials, resulting in thermal stability that is over 100 times better than most conventional glass mirrors.

While glass-ceramic materials like Zerodur and ULE exhibit near-zero thermal expansion and comparable resistance to thermal distortion, they fall short in terms of stiffness and fracture toughness. These attributes are critical for high-performance mirror applications. By comparison, SiC offers a more robust solution with its superior mechanical properties.

Advancing Optics with Novel Silicon Carbide Production Methods

The outstanding attributes of SiC have positioned it as a superior choice for the development of mirror optics and precision mechanical components. Although funding for development efforts has largely been necessary, the continued advancement in manufacturing processes is paving the way for broader adoption. SiC is redefining the standards for high-performance optical systems, making it a material of choice for the most demanding applications.

Stay tuned for upcoming blog posts where we dive deeper into this exciting material and its applications in optical manufacturing or visit our space optics resource page for more information.